PRODUCT CATEGORIES

LINKS

Products

20V single vane pump |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product name:20V single vane pump |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Item: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Details: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

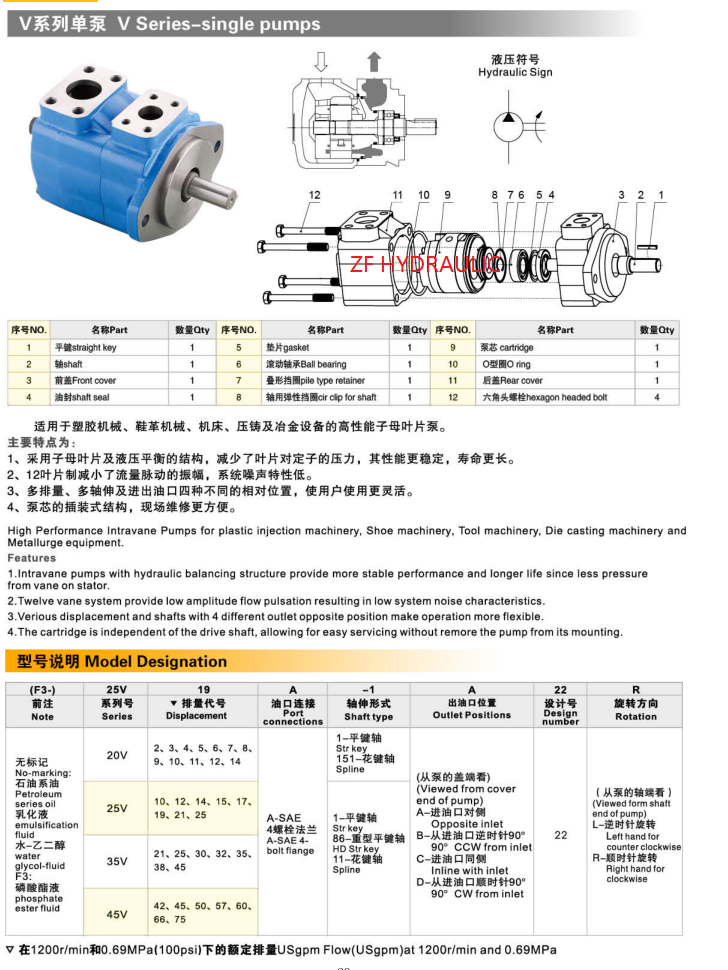

20V single vane pump How to order:    This type single vane pump other models: 20V 25V 35V 45V; 20VQ 25VQ 35VQ 45VQ

Check before work: please check before starting work. Especially for oil leakage, abnormal sound, and heat and other aspects of inspection. Note, if there is any abnormality, please immediately stop the operation of the pump and confirm the location of the abnormality. About maintenance management: in order to avoid unexpected accidents and operational difficulties caused by decreased capacity caused by perennial use, it is recommended to prepare spare parts such as oil seal kits. Most accidents are caused by fouling and deterioration of liquids used. Please be sure to change the oil regularly and carry out maintenance management. When using the motor in long-term storage state, abnormal sound, fever and other abnormal phenomena may occur. If there is any abnormality, please stop using it and check and maintain the motor.

Single vane pump

The pump is composed of rotor, stator, blade, oil distribution plate and end cover. The inner surface of the stator is cylindrical. There is eccentricity between rotor and stator. The blade can slide flexibly in the groove of the rotor. Under the action of centrifugal force when the rotor rotates and pressure oil flowing into the blade root, the top of the blade is attached to the inner surface of the stator. Thus, a sealed working cavity is formed between two adjacent blades, oil distribution pan, stator and rotor. When the rotor rotates counterclockwise, the blade on the right side of the figure extends outwards, and the volume of the sealing working chamber gradually increases, creating a vacuum, so the oil is sucked in through the oil suction port and the window on the oil distribution plate. It's on the left. As the blade retracts in, the volume of the sealing cavity gradually shrinks, and the oil in the sealing cavity is pressed out through another window of the oil distribution plate and oil pressure port 1 and exported to the system. This pump in the process of rotor rotation, oil suction pressure oil once, so called single action pump. The rotor is subjected to radial hydraulic unbalanced force, so it is also called non-balanced pump, its bearing load is large. The displacement of the pump can be changed by changing the eccentricity between the stator and rotor, so this pump is a variable pump.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

←[Previous:] [Next:]→ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Related Products : |